SOLIDWORKS CASE STUDY

Sailing into Direct Integration with J&J Design

Boat-building customers using SOLIDWORKS to accelerate design and manufacturing cycles.

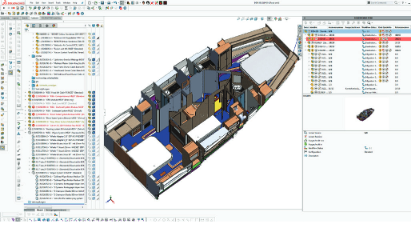

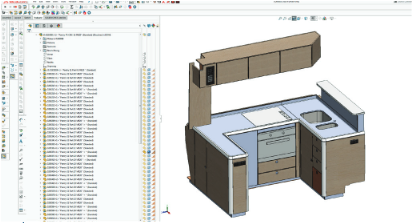

J&J Design relies on SOLIDWORKS mechanical design, analysis, electrical schematics, and product data management solutions to accelerate design and manufacturing cycles and reduce errors during the development of its award-winning boats and yachts.

Brothers Japec and Jernej Jakopin have a passion for boating, design, technology, and innovation. Since they founded J&J Design in Slovenia in 1983, the company has produced nearly 300 designs for 55 production boat builders from 22 countries, yielding more than 60,000 boats and yachts. Over the years, the company’s designs have won more than 100 boat of the year, design, and environmental awards, as J&J Design has built a reputation for quality, efficiency, and innovation.

The firm’s most recent creation—the R40 flybridge motoryacht— was designed for a large boat manufacturer. This latest yacht utilises new production technology and features unique lower and main deck accommodations that are coupled with a sporty, seaworthy hull of superior handling.

As J&J Design’s relationships with major boat builders have developed, so has the need to directly integrate its design operations with its customers, according to R&D Manager Martin Staric. “We’ve used a couple of CAD systems to design our boats in the past, but in 2014, a customer really pushed us to use SOLIDWORKS software, which is its standard design and manufacturing platform,” Staric recalls.

SOLIDWORKS

Faster Design to Manufacturing with Fewer Errors

Since implementing SOLIDWORKS solutions, J&J Design has seen the transition from final designs to its customer’s manufacturing operations move faster, with fewer design errors and less rework on the production floor. “Because we’re both on the same SOLIDWORKS platform, things move more quickly and there are fewer mistakes,” Staric stresses. “Roughly 80 percent of our SOLIDWORKS usage involves one customer, and in many ways we’ve become part of their design department.

Managing Team Growth

The move to SOLIDWORKS also helps J&J Design manage growth and build its design and engineering team. “When we acquired SOLIDWORKS in 2014, we had four engineers,” Staric recounts. “By 2015, we had 12 engineers, and by 2016, we grew to 20. Today, we have 30 people on the design and engineering team, and our electrical engineer has really taken to and embraced SOLIDWORKS Electrical software. The SOLIDWORKS implementation has helped us manage this type of growth because new team members typically don’t need training.

Eliminating Design Errors

“SOLIDWORKS is in some ways analogous to sailing,” Staric continues. “When you’re on the sea, you can sense the wind coming up as a fresh breeze. SOLIDWORKS is like that. SOLIDWORKS is fresh and there are well-thought-out ideas behind it. We’re certainly enjoying riding the SOLIDWORKS wave at J&J Design.” The firm implemented SOLIDWORKS Standard design, SOLIDWORKS Premium design and analysis, SOLIDWORKS Electrical Schematics Professional electrical design, and SOLIDWORKS PDM Professional software. By implementing SOLIDWORKS, J&J Design cut its design-to-manufacturing cycles, eliminated design errors and mistakes, improved revision controls and electrical schematics, and integrated directly with its largest customer’s PDM vault.

Challenge

Grow a yacht and boat design company – and a related specialty components and tooling business – by integrating and working more closely with leading boat manufacturers.

Solution

Implement SOLIDWORKS Standard design, SOLIDWORKS Premium design and analysis, SOLIDWORKS Electrical Schematics Professional electrical design, and SOLIDWORKS Product Data Management (PDM) Professional software solutions.

Results

- Cut design-to-manufacturing cycles

- Eliminated design errors and mistakes

- Improved revision controls, electrical schematics

- Ontegrated directly with largest customer’s PDM vault

10% Off Your First Licence

Further Information

Case Studies

Take a look at more case studies of SOLIDWORKS and 3DEXPERIENCE used in real workplace scenarios.

Free Learning Resources

Take a look at the huge range of free learning material available including videos, tutorials and documentation.